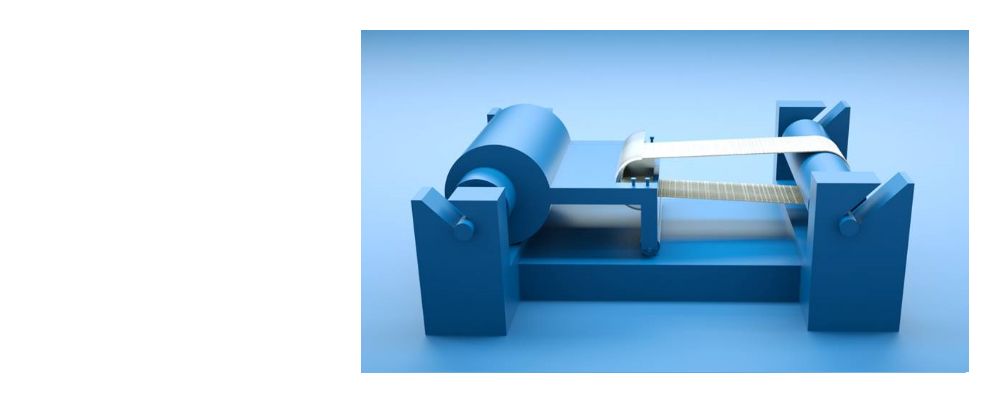

PROVIDING ENHANCED RESISTANCE TO ALL FORMS

OF CUT & ABRASION

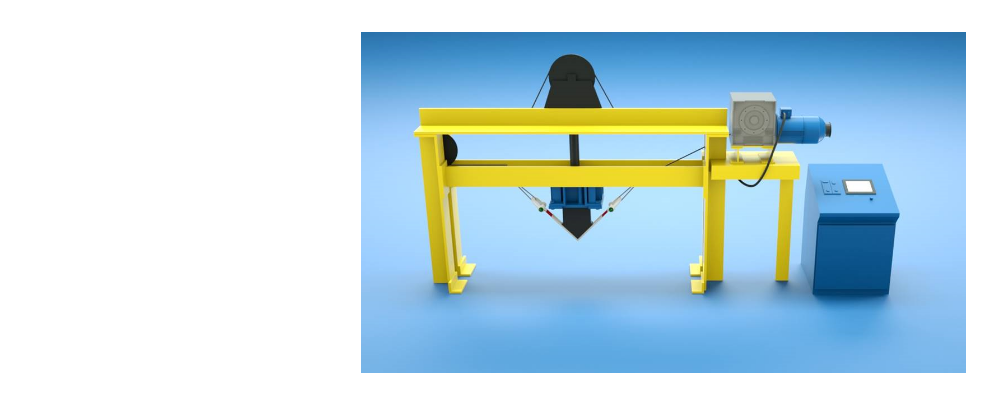

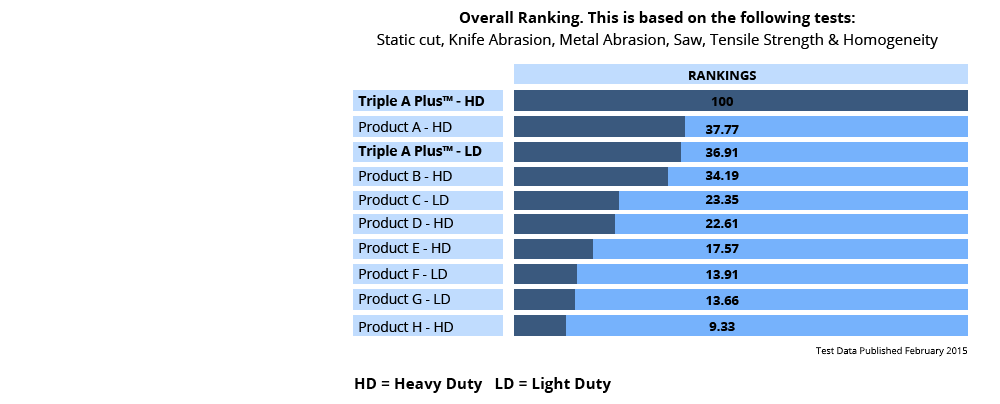

Synthetic sling failure caused by cut or abrasion can result in high value products being damaged, shipments incurring costly delays and in extreme cases personal injury and death.

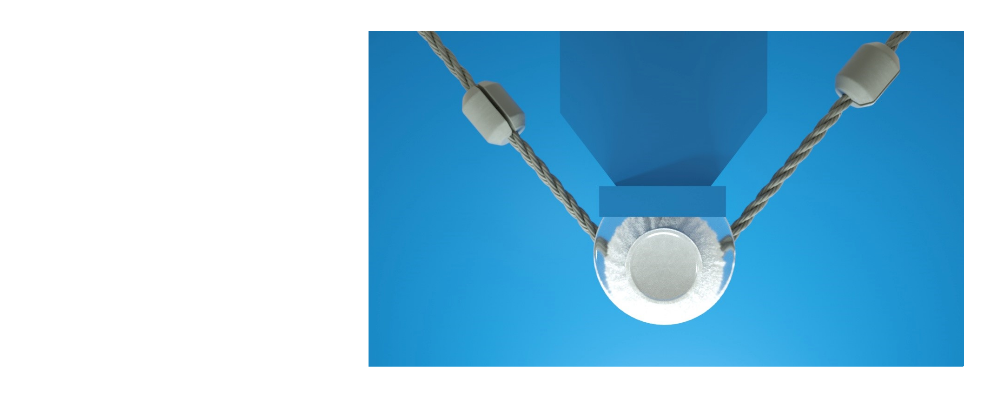

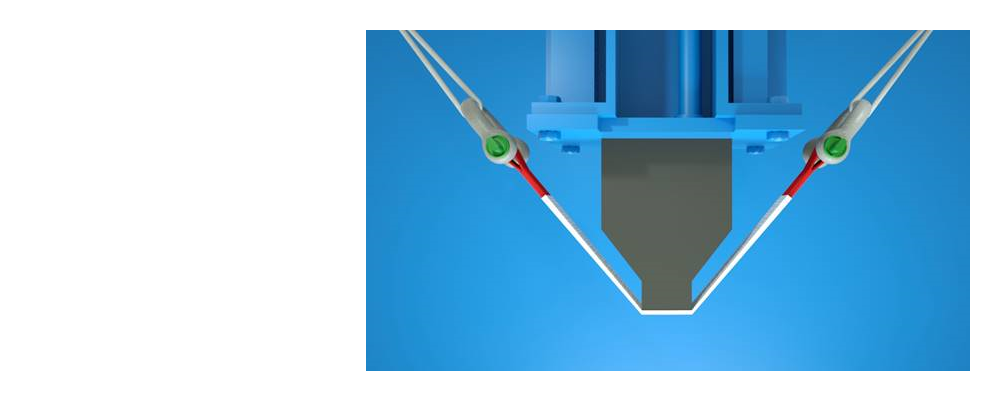

The Triple A Plus™ sling protection sleeve made with Dyneema® fibre and manufactured by the Worlds leading producer of multi-ply textile products, Marathon, is making lifting slings safer and helping organisations to avoid such risks.

QUICK CONTACT